Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd.'s newly-built air separation equipment and compressed air purification equipment production line project plans to carry out the completion acceptance of environmental protection facilities. The project is located in Chunjian Village, Chunjian Township, Fuyang District, Hangzhou. The production scale of the project is annual production of air separation equipment. 350 sets, 500 sets of compressed air purification equipment.

1. The project overview is as follows:

Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd. was established in 2010, located in Chunjian Village, Chunjian Township, Fuyang District, Hangzhou. It is an enterprise specializing in R&D and manufacturing of air separation equipment and compressed air purification equipment.

Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd. invested 30 million yuan to construct and manufacture air separation equipment and compressed air purification equipment projects. On March 11, 2015, the project was put on record by the Fuyang District Development and Reform Bureau (Fufa Gigong (Preparation) [2015] No. 58). In January 2017, the company entrusted Zhejiang Huanke Environmental Consulting Co., Ltd. to compile the "Environmental Impact Report on the New Air Separation Equipment and Compressed Air Purification Equipment Production Line Project of Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd.", and on February 8, 2017 Obtained the approval opinions issued by the Environmental Protection Bureau of Fuyang District, Hangzhou City on the environmental impact report of the project (Fuhuan Xushen [2017] No. 36). The approved production scale is 350 sets of air separation equipment and 500 sets of compressed air purification equipment. .

Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd. was put into trial production in October 2017. According to the actual production needs, the company carried out the production process, production equipment and plant layout under the condition of the same labor quota, product plan and production scale. Adjustment. The polishing process of the shot blasting machine is added to remove the saponification process in the bending process and the finishing process in the original EIA. The company leased the originally planned warehouse to Hangzhou Yiyi Filtration System Co., Ltd.

In order to successfully complete the environmental protection "three simultaneous" completion acceptance of the project, and at the same time facilitate the supervision and management of the environmental protection department, Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd. entrusted Zhejiang Environmental Technology Co., Ltd. to carry out the supplementary explanation of the environmental impact of the project. The Hangzhou Environmental Protection Research Institute Co., Ltd. of the Coal Science and Technology Group is responsible for the environmental supervision of the project.

2. The environmental protection measures of the project are as follows:

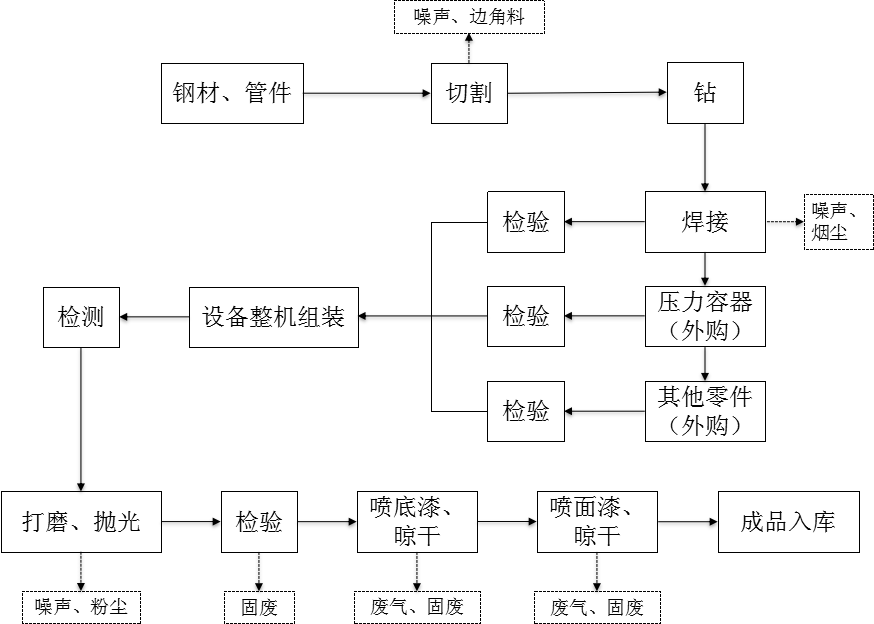

Figure 1-1 Project production process

Exhaust gas: The main exhaust gas pollutants of the project are paint exhaust gas, welding fume, grinding and shot blasting dust, and oil fume exhaust gas. The existing prevention and control measures are as follows:

(1) The paint spraying workshop and the drying workshop are the same workshop, which has been set up as a closed enclosure structure; the exhaust gas of the paint mixing and spraying room and the exhaust gas of the drying workshop are treated by the filter cotton + low temperature plasma + secondary activated carbon adsorption device. No less than 15m exhaust pipe discharge;

(2) The welding fume is discharged in the workshop without organization after being processed by the mobile welding fume purification device.

(3) The enterprise sets up an independent grinding and shot blasting area, and the grinding dust is discharged in the workshop after being processed by the mobile purification device, and the shot blasting dust is discharged unorganized after being processed by the vibrating filter cartridge dust collector.

(4) After being treated by the oil fume purifier, it will be discharged from an exhaust tube no less than 15m high

In terms of wastewater: the plant has done a good job of diversion of rain and sewage in the sewage pipe network system, and has set up grease traps and septic tanks to treat domestic sewage, and incorporate the sewage into the sewage pipe network system of the park.

In terms of solid waste: collected dust and leftovers can be sold to steel mills or scrap metal recycling factories for comprehensive utilization after centralized collection; project domestic waste is collected at designated points in the plant area, and then entrusted to the local sanitation department for unified removal and treatment; waste activated carbon generated , Filter cotton dust, waste paint buckets and other hazardous solid wastes have been temporarily stored in the hazardous waste temporary storage warehouse, and a disposal agreement has been signed with Hangzhou Lijia Environmental Service Co., Ltd.

In terms of noise: implemented as required, the workshop walls have been designed for noise reduction, hollow sound insulation walls have been designed, and double-layer sound insulation windows have been set up. Greening has been carried out around the plant area; the equipment in the workshop has been reasonably arranged, and the high-noise equipment shall be arranged in the middle of the plant area as far as possible.

3. Monitoring results of acceptance of project environmental protection measures:

The Fuyang Branch of Hangzhou Environmental Testing Technology Co., Ltd. conducted acceptance monitoring on the operation of the project in December 2017, and compiled the "Environmental Protection Facilities for the New Air Separation Equipment and Compressed Air Purification Equipment Production Line Project of Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd. Completion Acceptance Monitoring Report", according to the acceptance monitoring results, the main data are as follows:

1. Exhaust gas

(1) The emission concentration and emission rate of non-methane total hydrocarbons, xylene, particulate matter, and emission rate in the exhaust gas discharged from the paint spray booth of this project are in line with the "Comprehensive Emission Standard of Air Pollutants" (GB16297-1996) Table 2 of the new pollution source air pollution Organized secondary emission limit requirements; butyl acetate project is not evaluated.

(2) The emission concentration of oil fume meets the limit requirement of the maximum emission concentration of 2.0 mg/N.d.m3 in the “Emission Standard for Cooking Fume (Trial)” GB18483-2001.

(3) The treatment efficiency of the waste gas treatment system of this project is 91.0% non-methane total hydrocarbons, xylene >99.9%, butyl acetate 78.5%, particulate matter 80.3%, and soot waste gas 84.6%.

(4) The maximum value of ammonia at the four unorganized waste gas emission monitoring points at the factory boundary is 0.14mg/m3, the maximum value of hydrogen sulfide is 0.013mg/m3, and the maximum value of odor concentration is 19 mg/m3. The limit requirements of the second-level standard (new expansion and reconstruction) "factory boundary standard value of odor pollutants" in the Emission Standard (GB14554-93).

The measured concentrations of pollutants, non-methane total hydrocarbons, xylene, and particulate matter at the four unorganized waste gas emission monitoring points on the company's plant boundary comply with the "Comprehensive Emission Standard of Air Pollutants" GB16297-1996 Table 2 of the new pollution source air pollutant unorganized emission monitoring concentration Limit requirements, butyl acetate meets the environmental assessment.

2. Wastewater

The measured parameters of wastewater pH, COD, BOD5, animal and vegetable oils, and ammonia nitrogen at the company’s domestic sewage discharge outlets all comply with the maximum allowable discharge concentration of the second category of pollutants in Table 4 of the "Integrated Wastewater Discharge Standard" (GB 8978-1996), the third-level emission limit Value requirements, the measured parameters of ammonia nitrogen meet the requirements of the "Limits for Indirect Discharge of Nitrogen and Phosphorus Pollutants from Industrial Enterprises" (DB33/887-2013). The current wastewater discharge volume of this project is 600t/a, and the major pollutant COD and ammonia nitrogen discharge volume are respectively 0.06t/a and 0.002/a. The waste water and major pollutant discharge volume all meet the requirements of the total control index approved by the environmental assessment.

3. Noise

The noise value at the boundary of the enterprise complies with the emission limit of category 2 in the "Environmental Noise Emission Standard at the Boundary of Industrial Enterprises" (GB12348-2008).

4. Solid waste

The hazardous waste storage area of the project has adopted corresponding rainproof, anti-seepage and anti-loss measures, and is equipped with signboards, which basically meets the requirements of the "Hazardous Waste Storage Pollution Control Standard" (GB18599-2001). Hazardous waste is entrusted to Hangzhou Lijia Environmental Service Co., Ltd. for safe disposal; domestic waste is uniformly cleaned and transported by the environmental sanitation department of Fuyang City.

In accordance with the requirements for the acceptance of the completion of the environmental protection facilities of the construction project, the project list is now announced. Please consult the Fuyang District Environmental Protection Bureau for the specific environmental protection of the construction project. The public is welcome to participate in the environmental protection work of the construction project.

4. Publicity time:

May 17, 2018 - May 25, 2018

5. Contact information during the publicity period:

Contact number: 0571-63492919 Fax: 0571-63492916

Email: crsales@hzcrkf.com

The attachment download address of the environmental protection facility completion acceptance monitoring report: https://pan.baidu.com/s/1wVFyB3W53oBX1vjLrQtTkg

Construction unit: Hangzhou Chenrui Air Separation Equipment Manufacturing Co., Ltd.

May 17, 2018

咨询热线

+86-571-63492917